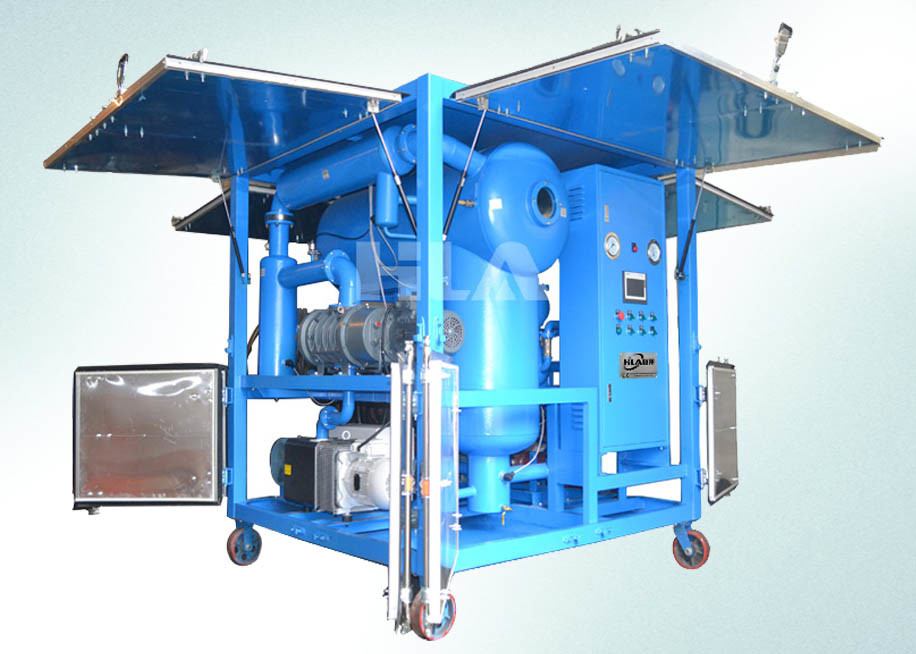

Horizontal Dielectric Insulating Mobile Oil Purifier , Mobile Oil Filtration Unit

Application:

Ultra-high voltage grid is regarded as “electric high way” which features big capacity .Distance and low loss, Until now ,there are 750KV,1000KV,±660KV,±800KV direct current in many countries, ulta-high voltage grids considering its safety, it has extremely requirement on insulating oil in transformer, mutual inductor and reactor.

The VPM series mobile Ultra-High voltage insulating oil purifier equipment ,manufactured by our company is effective in particles refining ,vacuum degassing and oil-water separation, This equipment has been successfully applied in 750kv alternating current and ±800kv key projects, and every oil treatment index reaches the national ultra-high voltage oil purification standard.

VPM Moveable Water-proof type Vacuum Insulating Oil Purifier is developed for transformer oil degasification, dehydration and filtration processing on site at outside. It adopts full enclosed structure with function of weather proof. The Transformer Oil Purifier Machine adopts double stages high vacuum system and horizontal vacuum separators. VPM Moveable Weather-proof type Transformer Oil Purifier with trailer can be carried out on road and off road. Meanwhile, it also works with other electrical insulating oil such as cable, circuit breakers, capacitor etc. The Purification Process of VPM Transformer Oil Purifier is able to maintain complete cleanness and improve dielectric strength of insulating oil.

Structure:

1. Equipped with two or more filters. There is a pressure gauge on the filter to monitor the pressure differential passed the filter. under normal operating temperature if pressure difference on the filter is more than 0.3Mpa, you must clean the filter.

2. Filtering system: Filter is cylinder shape and disposed vertically, for maintenance purposes. Filtering equipment

3. Heating system: Automatic temperature system control oil temperature in the range of 20~ 80 °C adjustable.These heaters are interlocked with pumps and vacuum pumps, heaters can only work when the oil pump and pump operation, both to ensure the safe operation of the heater, but also to prevent the generation

and oil aging"dead" oil zone, but also real-time monitoring the temperature of the heating system and controls the heater set temperature within a range of work; to avoid damage caused by dry heater.

4. Vacuum system: vacuum system consists of a vacuum separator, vacuum pumps, condensers, coolers and other components.

5. Automatic control system includes the liquid level controller, motor, and other components of the original protection.

6. Cooling system is made of the radiator, cooler, reservoir and other components. Separated vapor and other gases out of the vacuum evaporation , after passing through the radiator into the cooler, reduced to reservoir water is collected, and dry gas is a discharged from the vacuum pump, thereby protect vacuum pump.

7. Horizontal double vacuum separation technology, doubling the evaporation area and degassing time

8. Based on the high efficient vacuum oil purifier, Roots vacuum booster system and secondary high vacuum separation system are added, which enable the vacuum limit reaching ≤5Pa

9. Multi-stage precise filtration system with gradually increasing precision, which can effectively remove mechanical impurities from oil.

10. Fully automatic temperature controlling system and multi-stages electric oil heater adopts low-load design to ensure uniform heating oil, the load is less than 1.0W/cm2, oil level and temperature protection of heater, which avoid cracking and aging of oil.

11. Automatic defoaming system with dual electronic monitoring system, which avoid the foam ejecting and gushing to vacuum pump.

12. Online oil treatment, vacuum drying and vacuum oil-filling for electric equipment.

13. Advanced cooling system of vacuum pump, it reduces the frequency of oil’s replacement and extends the life of vacuum pump.

Technical Parameters:

| Model |

VPM200 |

| Capacity(L/min) |

200 |

| Vacuum level |

-0.06~-0.099 Mpa |

| Working pressure |

≤ 0.4 Mpa |

| Temperature range |

20 ~ 80℃ |

| Filtering precision |

≤1 micron |

| Breakdown voltage |

≥ 75KV |

| Water content |

≤ 3ppm |

| Gas content |

≤ 0.1% |

| Filtering particles |

≥ 99.5% |

| Power supply |

380V, 50HZ, 3PH (or customized ) |

| Working noise |

65 dB |

| Heating power (kw) |

110 |

| Total power (kw) |

120 |

| Inlet/outlet(mm) |

60 |

| Purifier Weight (kg) |

1500 |

| Trailer Weight (kg) |

650 |

|

Purifier

Dimension

(mm)

|

L |

1600 |

| W |

1300 |

| H |

1950 |

|

Trailer Dimension

(mm)

|

L |

3000 |

| W |

1300 |

| H |

1200 |

Index Of Purified Oil:

| Breakdown voltage |

≥ 75KV |

| Water content |

≤ 3ppm |

| Gas content |

≤0.1% |

| Filtering particles |

≥99.5% |

| Particles size |

≤ 1 micron |

| Cleanness |

≤ Grade 6 (NAS) |

| Processing by regeneration device as following (Optional device) |

| Acid value |

≤ 0.03 mgKOH/g |

| Water-solubility |

≥ 5.4 PH |

| Flash point (close cup) |

≥ 135°C |

| Dielectric- factor loss |

tgδ (90℃)% ≤ 0.005 |

Pre-sale service:

1. We have stock and can deliver within short time while you choose our standard machine,can deliver within 10 days for the machine produced as customer designed and requirements.

2. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

3. All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose:

1. We will count cheapest shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 2 working day after your payment

3. Email you the tracking no., and help to chase the parcels until it arrive you.

After-sale service:

1. We are very glad that customers give us some suggestion for price and products.

2. If you have any question,please contact us freely by email or telephone.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!